Module dimensions

Custom solar panels can be produced in any desired size, from 200 x 400 mm to 2200 x 3300 mm.

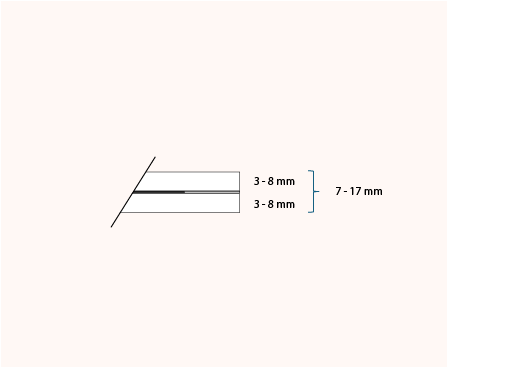

Glass thickness

Depending on the project’s inherent static constraints, a double-glazed structure is possible with:

- 3 + 3 mm

- 4 + 4 mm

- 6 + 6 mm

- 8 + 8 mm

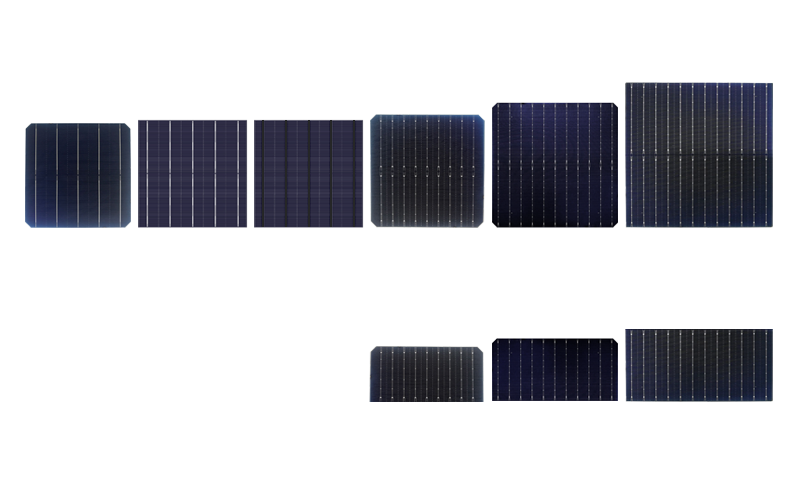

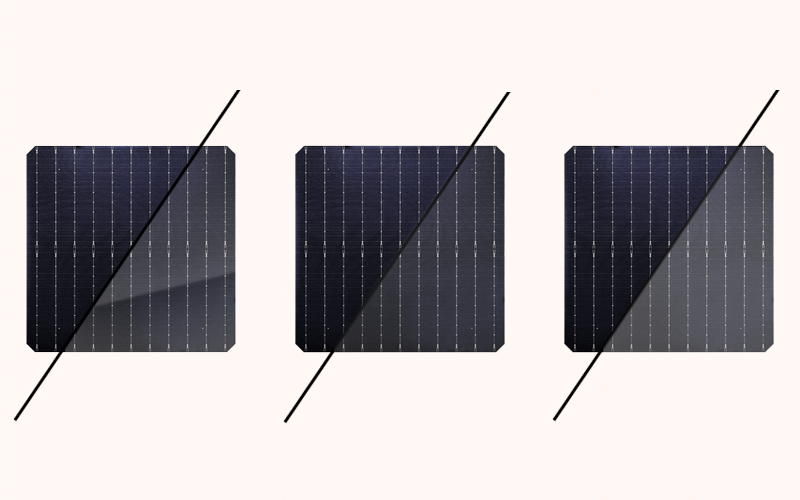

Cell types

The main cell types (M2, G1, M6, M10, M12) are available, also in half-cells, so you can always find the solution that maximizes efficiency according to the desired panel dimensions, or the solution that matches your desired visual aspect, with more or less visible or discreet cells.

The metallic connection ribbons can be hidden in black for some of the cell types, to give panels a uniform appearance, with no visible lines.

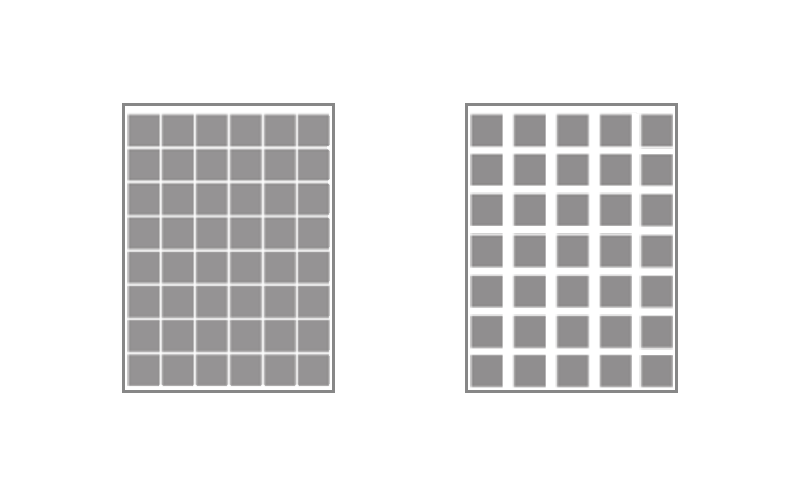

Cell spacing

In principle, cells are arranged in such a way as to maximize the module’s power, with narrow spaces between the cells, but if transparency is desired between cells, spacing can be increased, which obviously reduces the module efficiency.

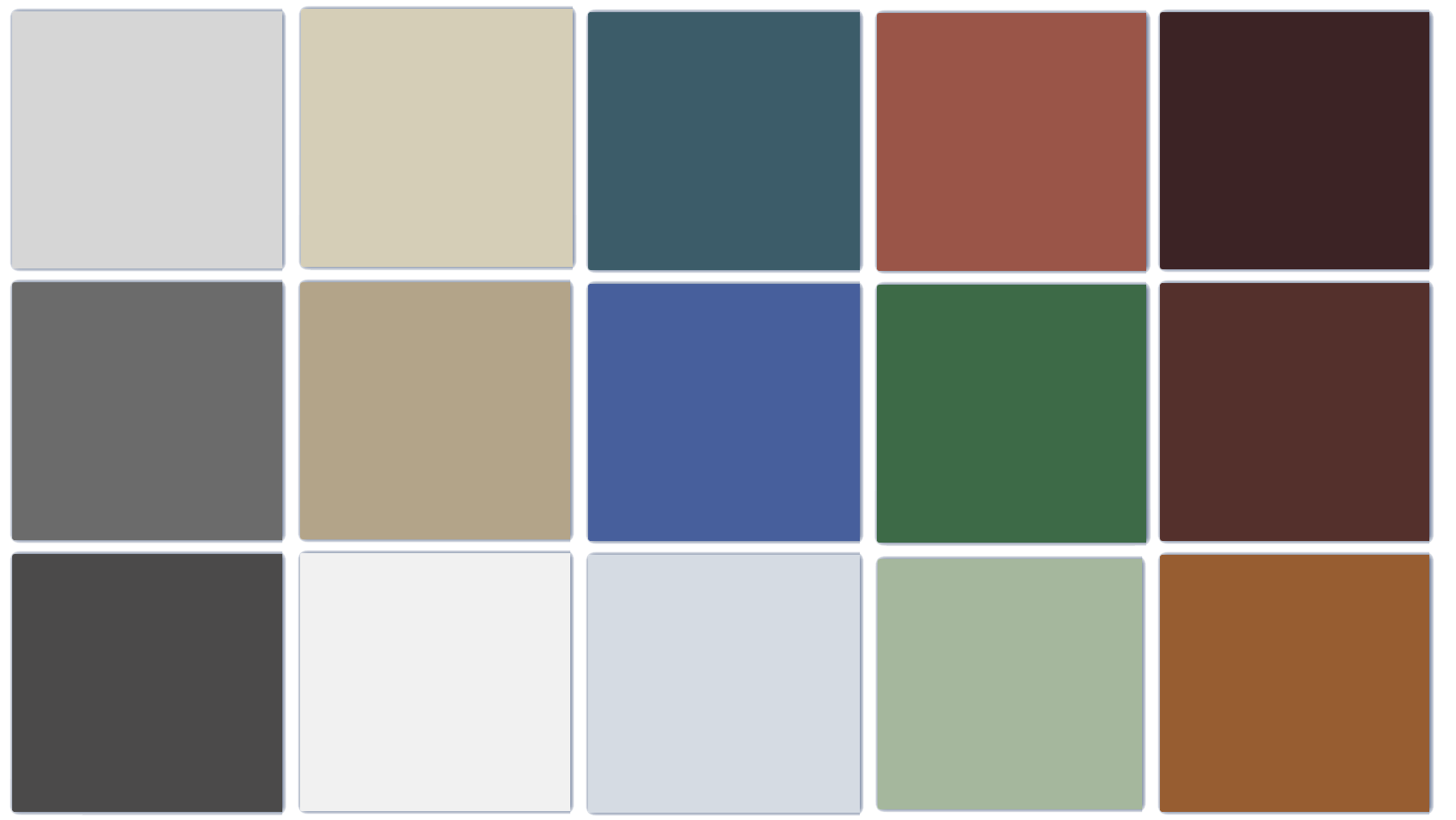

Color of frontglass

With standard transparent frontglass and with an opaque interlayer, the panel looks black or anthracite. Whenever color is required, we use the latest glass coloring technologies, based on interference layers, to minimize efficiency losses.

Frontglass surface

The panel’s front glass is available with a gloss, semi-matt or ultra-matt surface. Several types of special structured glass are also available.

Transparence

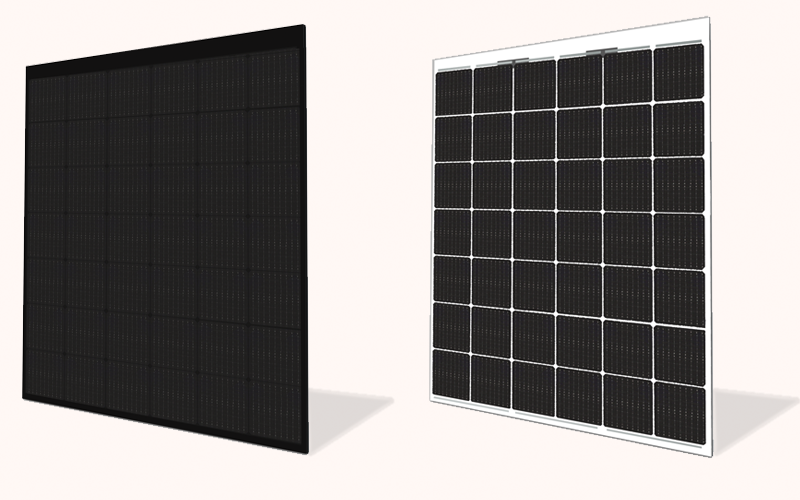

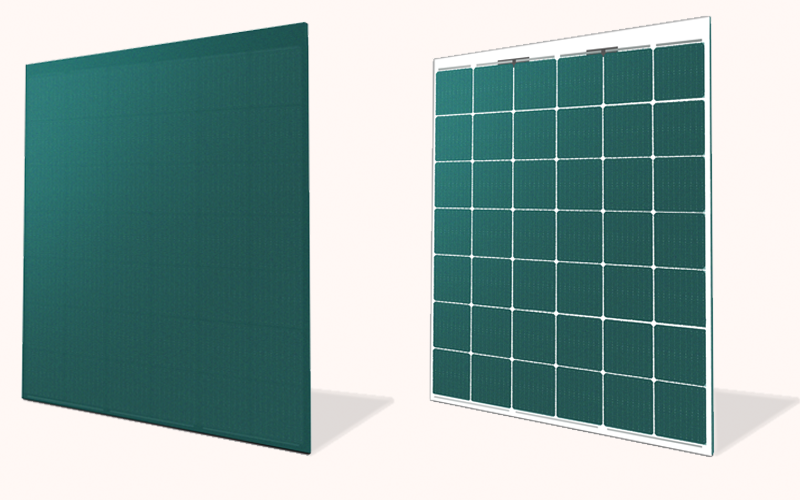

Panels can be produced with either an opaque or transparent interlayer, which in combination with colored or transparent glass allows a wide range of different appearances to suit architectural needs.

In combination with glass colored by interference layer technology, the panel appears uniformly the same color if there’s a black interlayer (left picture), whereas with a transparent interlayer only the cells appear colored, the space between the cells remaining transparent with a very slightly colored appearance.

Firesafety

In collaboration with our customers and construction partners, we ensure compliance with applicable fire safety standards, in Switzerland in particular, based on the “Transition document for fire protection planning and proof methods” drawn up by Swissolar, the umbrella association of the photovoltaic industry.

When required by fire insurance authorities, we supply the material needed for full-scale fire resistance tests (on the picture on the right, the structure erected for a fire test of the solar facades of the SUVA Malley-Phare building).

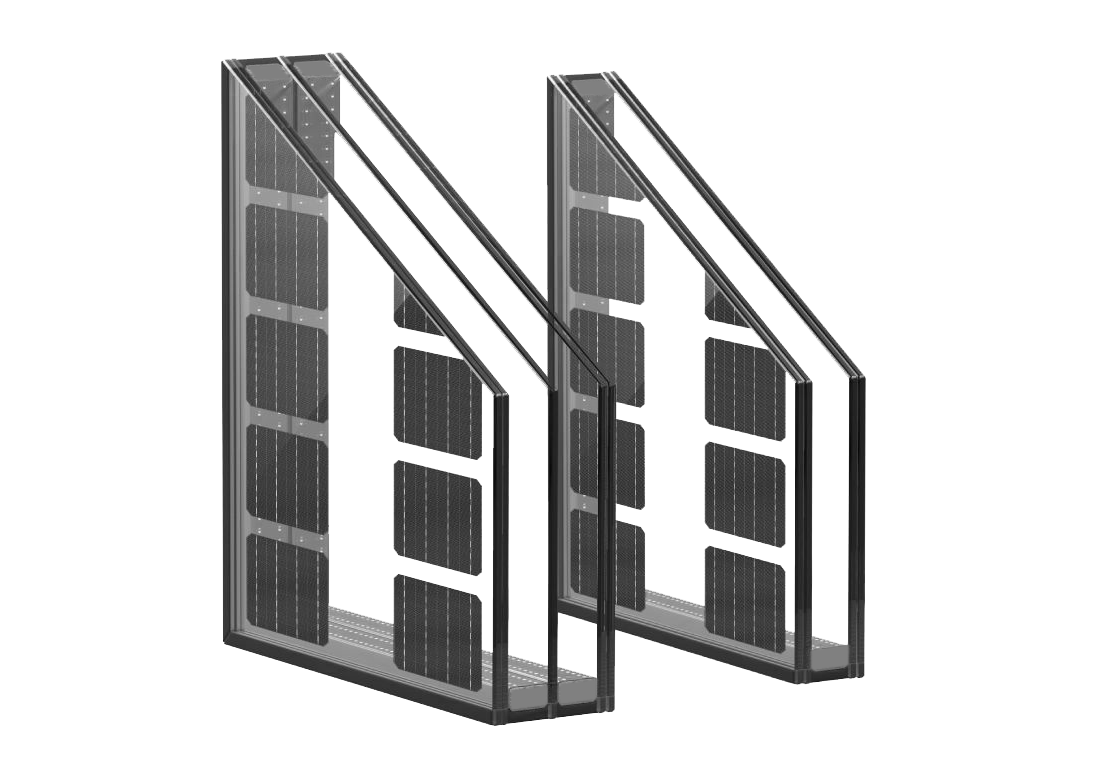

Insulated glass units (IGU)

The panels can be integrated into custom-made double or triple insulating glass units (IGUs), for integration into metal joinery or windows.